How To Make A Cabochon Bezel Setting

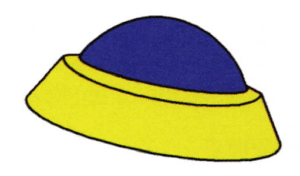

One of the almost basic designs in stone setting is Bezel Setting. Information technology is rudimentary in its concept, and information technology is very pleasing to the eye in its simplicity. This concept blends with the smooth vertical shape of the stone. In that location are no sharp corners, just gradual flowing lines to conform to the stone. Let'south delve into this different style of setting.

In an earlier article in Bench Magazine I showed how a round bur is re-shaped to have the same contours of the cab stone. This particular half-round/round bur, along with a proper execution, will enable you to perform and overcome any difficult bezel setting procedure.

The tools yous will need are: a very secure band clamp, a steel band-mandrel, a 3 ounce hammer with a 10 inch length handle, a steel hand held punch of 3 inches in total length and a copper or brass paw pusher. In addition you lot will demand a pillar file of #2 and #four cuts, flat edged pumice wheels of #180 grit, and #39 or a #40 Flat graver.

We volition now demonstrate the simplest version of a cabochon setting. It will make it easy to see what nosotros are working with if we use a 5x 7mm to 8x6mm stone.

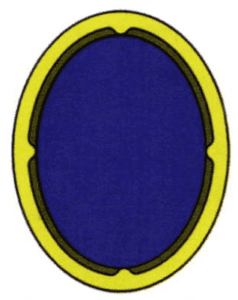

Tightly secure the band into your band clamp. I use a hammer to hit the clamp-peg tighter into the clamp. This will ensure a tight fitting, non-moving ring as we kickoff this setting process. With your #two cut colonnade file ascertain that the bezel walls are flat and not higher on ane side than the other. Overall and equal bezel elevation is very important at this juncture.

Briefly examine the internal areas of the bezel base for whatsoever picayune actress $.25 of gold that might be from a mistake in casting or a defect. Remove them with a pocket-size circular #006 bur. Place your cabochon rock on the top of the bezel wall. Is it over shadowing the metal in width and length? If and so, this is the adjacent phase in training. I use a rounded surface of a metal punch and ream open up the bezel walls to allow the rock to gently fall into place. With your finger on the stone, plough over the band and with a loupe view if the stone is fitting against the base of the bezel. There should be no space between the base of the stone and the bezel frame. This is very important!

If in that location is, you lot might accept a stone that is crooked or held up by a little bur of gold. If in that location is a lilliputian bur of gilded underneath the stone when hammer setting, there will exist lots of stress on this rock and and then you might finish up with a chipped stone.

Using my half-round/circular shaped bur, with the same overall equal dimensions or nearly the same profile as the cab, starting at the base of operations of the bezel wall, scrape the surface at equal increments. At each 1/4 turn dig into the gold a tad deeper. I will have at my disposal many sizes of these modified burs. I will gauge each bur against the right angle of the stone. This bur should non be used at a high rate of motor speed. Bank check often using your 10x power loupe at how you are progressing. Place the cab into this bezel recess.

Here are some questions for you now!

- Is the rock secured in the bezel?

- Are the walls of equal height?

- Are the walls of equal thickness?

- Is the stone properly aligned to the overall shape of the bezel opening?

If these 4 bones questions are answered favorably, you can now keep to the adjacent stage of setting.

I would like to underscore the reason to use a copper or contumely metal pusher. If you are going to total bezel an opal or soft stone, yous shouldn't be having any motility of that stone. I would have you lot utilise these ii selected pushers to just carefully press over the tip of the bezel. This way you lot will secure the metal to the surface. If y'all utilize a steel pusher and slip off the gold, y'all will definitely scratch the surface of the stone. Copper and brass are a lot softer and do non mark the rock.

If you are not certain well-nigh using a softer metal pusher, I have 2 other methods to hold the stone still while hammering the bezel down into the stone. The first is to use an elastic ring around the band mandrel and the stone. This will agree the stone in place while yous secure information technology with the bezel. The other method is to apply a touch of fast acting glue. This gum method will exist used only as a stop-gap measure out and is not intended as the best mode of cabochon setting.

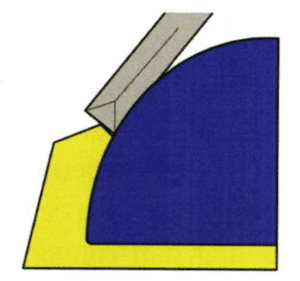

With the ring firmly placed on the steel ring mandrel hold your 3 inch metal punch firmly in your paw and proceed to hit this punch with swell care using your hand held hammer. Practice not hit hard, but only tap! Hold your dial at a 45 caste angle Abroad from the stone. When you lot see the metal starting time to printing against the stone, STOP! Turn the band around and outset the hammering of the other side of the bezel. You are at present starting to have the walls grip to secure the vertical sides of the rock.

Once this is done and the stone is feeling tight, remove the elastic band and begin the setting of the ends of the oval bezel setting.

Equally you work your style around the stone carefully make sure all of the walls are nicely holding the surface and that in that location are no spaces between the metal and the stone. Y'all tin now just tap to even-off the walls to make a smooth, even surface on the hammered section of the bezel wall.

I will at present use my flat graver to give a vivid-cut to the very inside of the bezel wall. This gives the band a clean and professional appearance. You should make sure that your graver is precipitous and vivid. This will leave a smooth inner surface cutting, confronting the rock, at testing to your higher setting abilities.

As this cutting is at present completed, you lot should employ either a triangular #4 cutting or your pillar file #4 and smooth file the areas where your hammer touched. In a smoothen flow of filing, rotate or file in a semi-circular fashion on the bezel wall tips only. Proceed in mind that you have two surfaces to be considered; the vertical wall and the 45 caste bending hammered facet. Make sure you accustom yourself with the #180 grit, flat faced pumice wheel, equally it is an important tool to exist familiar with.

Holding the ring in your hand, allow the dull rotating wheel to only remove the marks left past your pillar file. Do not let this pumice cycle touch your soft stone, as it will mark or destroy the surface you are so diligently trying to go on scratch free!

How To Make A Cabochon Bezel Setting,

Source: https://www.ganoksin.com/article/bezel-setting-cabochon-stones/

Posted by: flanaganligine.blogspot.com

0 Response to "How To Make A Cabochon Bezel Setting"

Post a Comment